- Enclosure construction

- Input systems

- System integration

- Mechanics

- Surface technology

Benefit from our experience and know-how

in the EMS

We are your competent partner for the following services and beyond

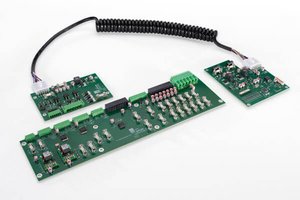

SMD

- Soldering paste printer

- Glue dispenser

- Hand soldering/fine soldering

- Fine pitch pick-and-place machine

- Vapor-phase soldering system

THT

- Flexible assembly stations

- Selective soldering machine

- Hand soldering/fine soldering

- Blank separation

Inspection

- Optical test

- Functional test

- Final test

Cable assembly

- Cable cutting to length

- Cable stripping

- Cable soldering

- Cable crimping

- Ribbon cable

- Round cable

- Cable set

- Cable harness

Assembly and mechanic components

- Module- and housing assembly - on request according to the specification EN ISO 13485 (medicine)

- Installation and vernier adjustment of mechatronic components

- Different gluing processes

- Protective lacquer coating and encapsulating of components

We are happy to assist!

+49 7081 9540-0 | Richard@WoehrGmbH.de

WÖHR sectors in one click